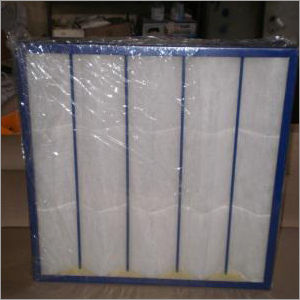

Mini Pleat Hepa Filters

Product Details:

- Connecting Type Flange/Panel integrated

- Filtration Grade HEPA

- Efficiency (%) >=99.97% @ 0.3 micron

- Pressure Initial pressure drop: 200-250 Pa

- Temperature Range Up to 80C

- Media Type Synthetic fiber/Glass fiber

- Cleaning Method Non-washable, replaceable

- Click to view more

Mini Pleat Hepa Filters Price And Quantity

- 1000.00 - 10000.00 INR/Piece

- 10 Piece

- Polyurethane adhesive

- Complies with EN 1822 / ISO 29463

- Neoprene or PU gasket for airtight seal

- Protective mesh/fiber face guard

- Pharmaceutical, Hospital, Cleanroom, Laboratory, Electronics

- Aluminum alloy or Galvanized steel

- White media, metallic frame

- 610x610x50 mm, 610x305x50 mm, custom sizes available

Mini Pleat Hepa Filters Product Specifications

- Flange/Panel integrated

- Industrial

- Up to 80C

- Approx. 3-7 kg (depends on size)

- Glass fibre

- Glass fiber media, Galvanized/Aluminum frame

- Fine mesh separator

- New

- Synthetic fiber/Glass fiber

- HEPA

- 500-2000 m3/hr (depends on size)

- Panel/Cartridge

- >=99.97% @ 0.3 micron

- Mini Pleat Hepa Filters

- Rectangular

- Non-washable, replaceable

- Depends on model size

- Mini pleated with separator, rigid frame

- Compact design, High dust holding capacity, Low resistance, Long service life

- Varies by model

- Initial pressure drop: 200-250 Pa

- Polyurethane adhesive

- Complies with EN 1822 / ISO 29463

- Neoprene or PU gasket for airtight seal

- Protective mesh/fiber face guard

- Pharmaceutical, Hospital, Cleanroom, Laboratory, Electronics

- Aluminum alloy or Galvanized steel

- White media, metallic frame

- 610x610x50 mm, 610x305x50 mm, custom sizes available

Mini Pleat Hepa Filters Trade Information

- 6000 Piece Per Month

- 15 Days

Product Description

Capitalizing on our years of industrial exposure and state-of-the-art manufacturing unit, we have been engaged in manufacturing, exporting and supplying excellent quality Mini pleat Hepa Filters. These filters are used in situations where high level of purity is needed. Finding application in pharmacy, chemistry and microbiology, the offered filters are manufactured using optimum quality raw materials and progressive techniques. Moreover, our valued clients can purchase these Mini pleat Hepa Filters at industry leading prices from us.

Key Features:

- Low initial pressure drop

- These filters have excellent dust holding capability

- Strong enough to withstand extreme air pressure

- Easy to use and exhibit extreme filtration

- Built with extra-ordinary perfection and have exceptional dimensional stability

- Have optimum filtration area and smooth finish

- Close pleated pre-filters for excellent suction

Specification

|

Filter Medium Material |

Micro glass filter, Paper Media |

|

Filter Type |

Box and Flange |

|

Type |

Mini Pleat Hepa Filters |

|

Brand |

United Make |

|

Flow Capacity Range |

50-2000 cfm |

|

Usage/Application |

Pharma / Hospitals / Process Plants / Automobile |

|

Size |

610 mm x 610 mm x 50 / 100 / 150 / 300mm |

|

Frame Material |

Aluminium |

|

Filtration Capacity Microns |

1 Micron - 0.3 Micron |

|

Micron Ratings |

Eu -9 Grade H13 Grade H14 Grade |

|

Thickness |

75 mm to 150 mm |

|

Initial Pr Drop |

11 mm WC |

Engineered for Precision Air Filtration

Mini Pleat HEPA Filters are meticulously engineered to deliver superior filtration in environments where air quality is paramount. The robust frame optionsaluminum alloy or galvanized steeltogether with an advanced sealing system using polyurethane adhesive ensure maximum filter integrity. Neoprene or PU gaskets create reliable airtight seals, reducing the risk of bypass and securing contaminant-free spaces for sensitive applications.

Dependable Standards & Versatile Applications

Meeting strict EN 1822 and ISO 29463 standards, these HEPA filters are trusted across multiple industries, including pharmaceuticals, hospitals, laboratories, and electronics. With their protective face guard and clean white media, theyre suited for both replacement and new installations. Choose from standard sizes or request a custom fit to match your specific cleanroom or equipment requirements.

FAQs of Mini Pleat Hepa Filters:

Q: How are Mini Pleat HEPA Filters installed for optimal airtightness?

A: Mini Pleat HEPA Filters are fitted with neoprene or PU gaskets and installed using their precision-engineered frames, ensuring an airtight seal that prevents any air bypass. This is crucial for maintaining the integrity of controlled environments such as cleanrooms and laboratories.Q: What industries typically use Mini Pleat HEPA Filters with metallic frames?

A: These filters are deployed in industries where air purity is critical, such as pharmaceuticals, hospitals, cleanrooms, laboratories, and electronics manufacturing. Their robust construction and compliance with international standards make them ideal for industrial and sensitive applications.Q: When should I replace a Mini Pleat HEPA Filter in my facility?

A: The replacement interval depends on usage conditions, contaminant load, and air quality requirements. Generally, filters should be monitored regularly and replaced whenever the pressure drop across the filter reaches manufacturer-specified limits or if air quality begins to decline.Q: Where can I procure Mini Pleat HEPA Filters in custom sizes?

A: Manufacturers and suppliers based in India offer standard and custom-sized Mini Pleat HEPA Filters to meet specific project needs. You can request custom dimensions beyond 610x610x50 mm and 610x305x50 mm to ensure precise compatibility with your equipment or facility.Q: What benefits do the protective mesh or fiber face guards provide on these filters?

A: Protective face guards (either mesh or fiber) shield the filter media from physical damage during installation and operation, extending service life and ensuring consistent airflow and performance over time.Q: How does the filters compliance with EN 1822 / ISO 29463 impact performance?

A: Filters tested and approved to EN 1822 and ISO 29463 guarantee high-efficiency particulate removal, providing assurance of performance in capturing airborne contaminants and safeguarding sensitive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+